BC Group News

BC Group's

Updates and Information in Regards to COVID-19

At BC Group International, Inc., there is no higher priority than

the health and safety of our employees and community. There is no

time more important than now in delivering lifesaving, quality

products and services to those in need. Click the link below to

stay up to date on the latest from BC Group in regards to the

COVID-19 pandemic.

https://bccalibrationservice.com/bc-group-covid-19-notification/

BC

Biomedical’s IPA-3400 Infusion Pump Analyzer Now Patented

The IPA-3400 Infusion Pump Analyzer is now patented under US Patent

No. 10,100,828. Its cutting-edge, patented design uses a dual

syringe stepper motor driven system that provides continuous

monitoring of the fluid flow without the need to stop and perform

intermittent drains like older technologies do. This provides a more

realistic flow path for the Infusion Device under test and therefore

more accurate readings. Also, independent stepper motor control of

the custom designed ceramic valving allows the system to run not

only more quietly and more smoothly, but it also allows for a

bidirectional powered fluid flow for use in the built-in cleaning

cycle.

GE Healthcare’s Global Ultrasound Division

Establishes New

Procedures for Testing the Safety of their TEE Ultrasound Probes

Sophia Antipolis, FRANCE and St.

Charles, MO USA - GE Healthcare - a worldwide

leader in TEE Ultrasound Imaging systems and BC Group International,

Inc., a leading manufacturer of test equipment for the medical

industry, announced after months of testing by the GE Healthcare’s

Global Ultrasound Division, a new procedure for testing the safety

of their TEE Ultrasound probes has been established.

Ken O’Day, Vice President Sales and

Marketing for BC Group said, “testing TEE probes for electrical

leakage has always been a recommended procedure and effective

December 2015 the Intersocietal Accreditation Commission (IAC)

Standards and Guidelines for Adult Echocardiography Accreditation

went into effect.“

Section 2.2.3B of the standard

states:

“The manufacturer’s guidelines must be followed for the

appropriate care and cleansing of the TEE transducer and adhere to

the appropriate infectious disease standards to prevent the

transmission of disease. Effective December 31, 2015, the structural

and electrical integrity of the transducer must be checked between

each use, using an ultrasound transducer leakage tester. “Passed” or

“Failed” must be documented in the routine TEE probe cleaning /

maintenance log along with action taken if “failed.”

GE Healthcare’s Cardiac Segment

Leader, Global Ultrasound Probes, Daniel Vignet, headed up a team of

Engineers who performed the testing and established the leakage

limits as well as the additional procedure for testing the GE TEE

probes.

“Historically the Electrical leakage

testing for Ultrasound probes was performed by the Biomedical or

Clinical Engineering Department on a scheduled bases,” stated O’Day.

“With the IAC regulations, the responsibility for testing the probes

has shifted to the Ultrasound or Cardiology Departments, since the

test now needs to be performed after every usage. Although the

testing requirement is designed for patient safety, a side benefit

is the detection of small problems with the TEE probes before major

damage occurs,” O’Day went on to say.

The new recommended guideline just

established by the GE Engineering group will now take the testing

one step further to include the deflection controls as well as

testing for leakage caused by bite holes, damage or other breaks in

the sheath of the TEE probes. All TEE Probes need to be tested for

electrical leakage, however the GE Ultrasound Probe Models 6VT-D,

6Tc and the 6Tc-RS will require the new additional testing. For more

information on what is needed and how to perform this new test

procedure, go to our BC Group Store and download the

Quick Start Guide. If you're using

CS Medical's TD 100®, you can download the

TD 100 Quick Start Guide.

The ULT-2020 Ultrasound Leakage

system is designed, manufactured and serviced by BC Group

International, Inc. under the BC Biomedical product label, at their

corporate headquarters in St. Charles, MO. BC Group is ISO-9001:2015

Certified, ISO-13485:2016 Certified, ISO-17025:2005 Accredited, FDA

Registered & Inspected, and FDA CGMP Compliant.

The ULT-AC-10 and ULT-SP-20 are available in the GE ULT Testing Kit

(BC20-42350) or you can purchase the items separately below.

View the ULT-2020 Ultrasound

Leakage Tester.

View the

BC20-42350 GE ULT Testing Kit.

View the

ULT-AC-10 Adapter.

View the

ULT-SP-20 Splitter.

For further information visit the BC

Group online store to learn more about their product

portfolio, how to purchase, for valuable information and tips on

testing TEE probes.

Preorder the NEW AA-8000 Anesthetic

Agent Analyzer

The

AA-8000 is the latest in

portable anesthetic agent analyzers. It was designed to meet the

demand for a small, easy to use unit with high reliability and

accuracy. Utilizing proprietary state-of-the-art digital NDIR

(Non-Dispersive Infrared) Technology, the AA-8000 provides a low

cost, high function, microprocessor-based analyzer that is simple to

operate while maintaining high performance and accuracy.

The unit’s flexible

design and portable size makes it the ideal service tool for

anesthesia service applications in hospitals and surgical centers.

It has a slanted display and adjustable handle/stand to allow for

ease of viewing. The internal rechargeable Lithium battery provides

for hours of continuous operation.

One button selection

of the agent to be analyzed coupled with one button control over the

built-in sampling pump make the unit simple and quick to use. No

complex menus and key combinations are required. The internal data

logger combined with the internal clock allows for the storage of up

to 250 time and date stamped readings, that can be downloaded to a

computer using the USB interface.

Flash Memory and the

USB interface allow for field upgrades with downloads from our

website. Some other features of the AA-8000 include:

•

Measures four Anesthetic Agent Gases: Sevoflurane, Isoflurane,

Desflurane and Halothane

•

Measures four Anesthetic Agent Gases: Sevoflurane, Isoflurane,

Desflurane and Halothane

•

Large Graphical Display with Backlight

•

Auto compensation for Temperature and Barometric Pressure

•

Gas Flow Sampling at 200 ml/min

•

Manual and Automatic operation

•

Fast warmup time

•

Comes with NIST Traceable Calibration Certificate with Data

•

Service Tool for anesthesia service application (NOT FOR CLINICAL

USE)

• Made in USA

The AA-8000 is expected to be shipped by third quarter 2018. If you

would like more information about the AA-8000, please contact us at

314-636-3800 or by email at sales@bcgroupintl.com. You can also view

our complete line of biomedical test equipment, including over 75

different product lines at

BCGroupStore.com.

Celebrating 30 Years with BC Group!

This year BC Group

is celebrating its 30th Anniversary! BC Group has been

your One-Stop Biomed Shop for three decades and will continue to

strive toward exceeding customers expectations.

BC Group was

founded in 1988 in St. Louis, Missouri. Upon start up, BC Group was

formed as a sales and service organization to handle the test

equipment needs of the biomedical engineering community. Over the

past 30 years, BC Group has grown to include over 75 different

product lines with thousands of products. This includes BC Group’s

own unique product line of BC Biomedical labeled products.

While BC Group may

have initially started as a sales and service organization, in 2000

BC Group began manufacturing and private labeling their own product

line under the now familiar BC Biomedical label. They now have

product families in almost all modalities.

Another milestone

for BC Group was in January of 2005, when Lloyd Industries, the

company that engineered and manufactured most of the BC Biomedical

brand products, purchased BC Group. This acquisition provided BC

Group with the engineering and manufacturing resources to expand. BC

Group, under the BC Biomedical brand, is now one of the largest

manufacturers of biomedical test and measurement equipment in the

world.

One of BC

Biomedical’s most memorable moments was the introduction of the

ESU-2400 Electrosurgical Unit Analyzer at the 2009 AAMI Expo. The

ESU-2400 was a groundbreaking new piece of equipment, shattering all

previous limitations for high-end electrosurgery analyzers.

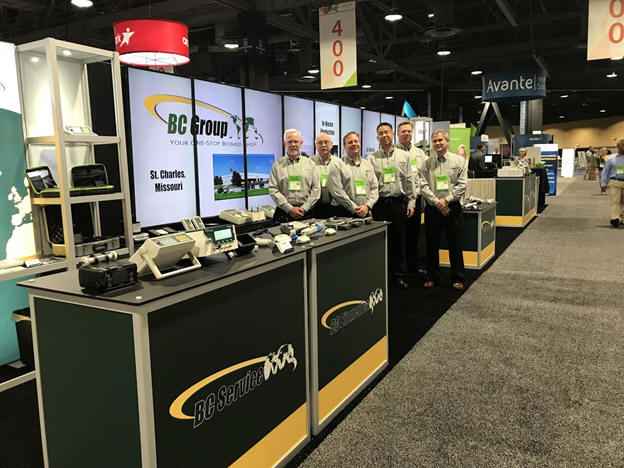

(BC Group at AAMI 2018)

BC Group was

recently issued a patent for the DFA2 Technology in the ESU-2400H

Electrosurgical Unit Analyzer. Under US Patent No. 9,883,903, the

ESU-2400H aggressively digitizes the complex RF waveforms produced

by electrosurgical generators. Each data point is analyzed to

provide highly accurate measurement results. This is the only ESU

Analyzer on the market capable of testing the latest generation of

ESU Generators.

BC Group has a

major commitment to Quality at all levels of their operation. The

company is certified to ISO 9001:2015 and ISO 13485:2016. Their

Service Center is accredited to both ANSI Z540-1 and ISO/IEC

17025:2005 with full traceability to NIST. They are Registered with

and Inspected by the FDA and follow the Good Manufacturing Practices

(GMP) as well as comply with the QSR (Quality Systems Regulation)

21CFR820.

Throughout the past

30 years, BC Group has maintained their promise as a “One-Stop

Biomed Shop.” BC Group aims to provide all the equipment, tools,

supplies and service that the biomedical community might need. BC

Group not only offers an extensive list of test equipment

manufactured by themselves and their partners, but they also provide

labels, cables and everything in between. Depot and Onsite

calibration service is available for just about all test equipment

on the market.

For more

information about BC Biomedical test equipment, please contact BC

Group by phone at 1 (314) 638-3800 or through email at sales@bcgroupintl.com.

You can also view their complete line of BC Biomedical products,

including pricing, datasheets, manuals and more, online at

www.BCGroupStore.com.

This year BC Group

is celebrating its 30th Anniversary! BC Group was founded in 1988 in

St. Louis, Missouri. Upon start up, BC Group was formed as a sales

and service organization to handle the test equipment needs of the

biomedical engineering community.

Kristi Boyce, Lisa

Clotfelter and Mike Clotfelter (third, second and first from the

right), joined other Georgia Biomedical Instrumentation Society

members as they witnessed Governor Nathan Deal sign the Proclamation

Healthcare Technology Management Professional Appreciation Week at

the State Capitol. HTM Professional Appreciation Week celebrates

biomedical technicians, clinical engineers, biomedical engineers,

medical equipment technicians and anyone that is involve with the

sales, service and maintenance of medical instrumentation.

BC Group

Now Has International Calibration Options

BC

Group International is located in St. Charles, MO, which is located

in the USA. We offer factory calibration and repair services at this

location for the test equipment that we manufacture under our BC

Biomedical brand. Due to high shipping costs and down-time, we’ve

been looking into global options for calibration services for our

test equipment. Some of our products must be returned to our

facility in St. Charles in order to have a full calibration

performed on automated test rigs, but manual calibrations can often

be performed in well-equipped calibration labs. Below is a list of

our partners or firms who have obtained factory service training at

our facility in the last few years. BC Group International does not

accept any liability for the work or service provided by these

alternate calibration laboratories.

BC Group

International - St. Charles, MO USA (Worldwide Headquarters)

• www.bcgroupintl.com

• service@bcgroupintl.com

Biosancta – Columbia

• www.biosancta.com

• direccioncomercial@biosancta.com

• direccionlaboratorio@biosancta.com

Calibration Experts Co. Bahrain

• md@cec.bh

Energy Distributor – Saudi Arabia

• http://www.ed.com.sa/

• info@ed.com.sa

Folath Medical Technology - Saudi Arabia

• Folath@folath-med.sa

GMC-I in Nuremburg Germany

• http://www.gmci-service.com/en/general.html

Smart Instruments (M) Sdn Bhd Malaysia

• contact@smartinstruments.com.my

• www.smartinstruments.com.my

BC

Group to Host a Series of Electrosurgery Courses

BC Group is pleased to announce quarterly ESU courses

at our facility, located in St. Charles, MO. The first of this

on-going series will be held July 16-20, 2018. During the five-day

curriculum, students will have the chance to obtain invaluable

information on one or more Valleylab generators. The instructor,

Dale Munson, is the former, principal instructor at Medtronic, but

now owner of Biomed Support Services.

The following course schedule will allow students to

select the exact course(s) they need.

• One-day course

(FT10)...................................................................................................................................................................................Friday

• Two-day course (Force FX™ -C OR ForceTriad™)...................................................................................................................Mon-Tues

or Wed-Thurs

• Three-day course (ForceTriad™ &

FT10™)....................................................................................................................................................Wed-Fri

• Four-day course (Force FX™ -C & ForceTriad™.........................................................................................................................................Mon-Thurs

• Five days (all three generators w/ additional lab

time and fault isolation tips and

tricks).......................................................................................Mon-Fri

For questions about registration, pricing, travel

planning and specific topics, contact Dale Munson at 303-525-3393

or mail@biomedsupportservices.com.

BIOMED SUPPORT SERVICES

2631 Crooked Vine Court | Colorado Springs, CO 80921

dale@biomedsupportservices.com |

www.biomedsupportservices.com | 1-303-525-3393

BC

Biomedical’s DFA2 Technology in the ESU-2400H Now Patented

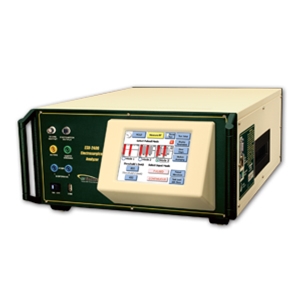

BC

Biomedical’s ESU-2400H Electrosurgical Unit Analyzer’s DFA2

Technology is now patented under US Patent No. 9,883,903. The newly

patented technology allows the ESU-2400H to aggressively digitize

the complex RF waveforms produced by electrosurgical generators.

Each data point is analyzed to provide highly accurate measurement

results.

The

ESU-2400H is able to digitize complex RF waveforms due to its low

impedance internal load bank, which has a wide range of 0 to 6400

ohms, in as little as one ohm increments. It is a microprocessor

based analyzer that utilizes a combination of unique hardware and

software to provide accurate and reliable test results, even from

“noisy” electrosurgical generator waveforms such as “Spray”.

The

ESU-2400H is able to digitize complex RF waveforms due to its low

impedance internal load bank, which has a wide range of 0 to 6400

ohms, in as little as one ohm increments. It is a microprocessor

based analyzer that utilizes a combination of unique hardware and

software to provide accurate and reliable test results, even from

“noisy” electrosurgical generator waveforms such as “Spray”.

The

ESU-2400H, unlike most conventional ESU analyzers, has internal high

voltage setup relays to control the measurement path. This allows

the user to switch between power measurements, leakage measurements,

REM/ARM/CQM testing, or even run an autosequence that could include

any or all of these tests – without even moving wires around.

The

current transformer internal to the ESU-2400H senses the RF current

flowing through the internal test load and produces a ratiometric

voltage, which is digitized and analyzed by the microprocessor.

Combining the standard and low ranges of the ESU-2400H with the use

of the current transformer, the user has full control over the

ability to get high accuracy and high-resolution readings from all

types of electrosurgical generators.

If you would like more information about the ESU-2400H, please

contact us by phone at 1 (800) 242-8428 or through email at sales@bcgroupintl.com.

You can also view our complete line of BC Biomedical products,

including pricing, datasheets, manuals and more, online at www.BCGroupStore.com.

BC

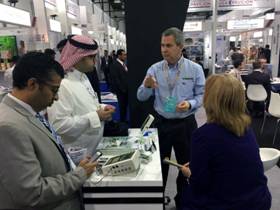

Group Attends Arab Health 2018

BC Group International traveled to Dubai in January

to exhibit at Arab Health 2018. BC Group partnered with the state of

Missouri and several other Missouri companies in a large state

pavilion to welcome attendees from all around the world. Arab Health

is a four-day medical trade show that is held each year at the Dubai

International Convention and Exhibition Center with over 4000

exhibitors and more than 100,000 attendees. In addition to meeting

and talking with attendees from diverse medical backgrounds, BC

Group also had the privilege to welcome two of our international

dealers from Pakistan and Lebanon. BC Group International will

continue to exhibit at Arab Health and other international

tradeshows in our efforts to be “Your One Stop Biomed Shop”.

BC Group Hosts

Three Day Training for International Dealers

On

March 13-15th, 2018, BC Group International hosted six of our

international dealers from five different countries for Technical

Service Training. Malaysia, South Africa, Guatemala, Columbia and

Saudi Arabia were all represented in the three-day training.

The

training began with a tour of the BC Group offices and manufacturing

facility. After the tour, the attendees spent eight hours each day

learning the specifics and features for our BC Biomedical product

lines. Instructed by our engineering manager, Lucio Simoni, the

attendees learned about the ESU-2400 Series, NIBP-1000 Series, the

new IPA-3400 and more. After a condensed introduction on each

product, attendees also learned how to calibrate each of the BC

Biomedical product lines.

For

many of the dealers this was their first trip to St. Louis, and

unexpectedly their first snow. They enjoyed a trip to the famous

Gateway Arch and tried several different local restaurants,

including the famous St. Louis style pizza and frozen custard. The

training was both informative and enjoyable for the dealers and BC

Group employees as we learned from each other about the biomedical

field in each country.

To

find a BC Group dealer near you, visit our Dealer

Page.

Visit our online

store for

more information about our products, including pricing, manuals,

videos and more.

BC Group

Obtains New ISO Certifications

BC

Group has been certified by Orion Registrar, Inc. to be in

compliance with the new ISO 13485:2016 Quality Standard. The new

certification applies to BC Group’s design, manufacturing, sales and

calibration of electronic and mechanical inspection, measuring and

test equipment. BC Group has also been certified to be in compliance

with the new ISO 9001:2015 Quality Standard.

BC

Group has been certified by Orion Registrar, Inc. to be in

compliance with the new ISO 13485:2016 Quality Standard. The new

certification applies to BC Group’s design, manufacturing, sales and

calibration of electronic and mechanical inspection, measuring and

test equipment. BC Group has also been certified to be in compliance

with the new ISO 9001:2015 Quality Standard.

The

new ISO 13485:2016 Standard has a few updates to the ISO 13485:2003

Standard. According to the International Standard for Organization, one of the biggest changes that the new

ISO 13485:2016 has is a greater emphasis on risk management and

risk-based decision making. There are also changes related to the

increased regulatory requirements for organizations in the supply

chain.

Standard for Organization, one of the biggest changes that the new

ISO 13485:2016 has is a greater emphasis on risk management and

risk-based decision making. There are also changes related to the

increased regulatory requirements for organizations in the supply

chain.

The

International Standard for Organization describes the changes to the

new ISO 9001:2015 Standard as an upgrade to a new High-Level

structure, making it easier for anyone using multiple management

systems. It also places more emphasis on risk-based thinking.

What

does this mean for consumers? It means BC Group is committed to

enhancing customer satisfaction through the continual improvement of

not only their products and services, but also their Quality

Management System. To help us meet these updated standards, we have

rolled out a new risk assessment program in 2018. We are using it

across all areas of the company to identify issues before they

happen and implement appropriate preventive actions. BC Group is

dedicated to exceeding customer expectations, which is why BC Group

has been ISO Certified for over a decade.

BC

Group’s Quality Programs include:

ISO

9001:2015 Certified

ISO

13485:2016 Certified

ISO/IEC

17025:2005 Accredited

ANSI

Z540-1 Accredited

FDA

Registered & Inspected

NIST

Traceability

View

BC Group’s new ISO

13485:2016 Certification.

View

BC Group’s new ISO

9001:2015 Certification.

BC Group Receives Award for Excellent Sales Performance

BC Group was recently selected to receive the Imtmedical (IMT

Medical) Award for Excellent Sales Performance for the year ending

2017. IMT Medical is located in Buchs, Switzerland and manufactures

ventilators, ventilator analyzers and test lungs that are used by

biomeds worldwide.

BC Group distributes the IMT product line under our BC Biomedical

label and has North America as our exclusive territory. Our PFC-3000

series of ventilator testers measures flow, pressure, temperature,

humidity and O2 concentrations bi-directionally. The one-of-a-kind

adult, pediatric and high frequency ventilation measuring modes make

the PFC-3000 the ideal calibration tool for all ventilators,

anesthesia machines and spirometers. The PFC-3000 distinguishes

itself from other calibration tools by combining a simple, intuitive

multilingual user interface with the highest precision tester. With

the push of a button, all measured values can be stored directly on

the PFC-3000 and later retrieved for documentation purposes.

Learn more about the PFC-3000.

BC Group also distributes the IMT Mobile Gas Flow Analyzer - Citrex

H5 and Citrex H4 under the IMT product label.

Learn more about the Citrex H5 Mobile Gas Flow Analyzer.

In addition, BC Group distributes the complete Lung Simulator

products with the BC Biomedical product label.

Learn more about lung simulators.

BC Group is proud to be the authorized service center for the IMT

products in North America, providing service on our PFC-3000, as

well as the PF300 products from IMT.

Popular Biomedical

Training Instructor Launches New Business

Quality training is

essential for the Biomedical profession, but it’s often hard to

find. BC Group is proud to endorse and recommend this new and

innovative option for our industry.

Dale

Munson, a popular training instructor in the biomedical community,

has launched his own business; Biomed Support Services. Biomed

Support Services strives to build technical competence in biomedical

technicians and clinical engineers. Biomed Support Services include

creating simple-as-possible training materials, presenting

customized courses, recommending process improvements and performing

a variety of technical support functions (calibrations, output

verifications, PMs, etc.).

Biomed

Support Services has more than 40 years of designing and developing

technical training materials. The primary objective at Biomed

Support Services is to improve job performance so hospitals can keep

their medical equipment reliable, safe and available for use. By

maximizing equipment up time, hospitals can extend the useful life

of their equipment and reduce the total cost of equipment ownership.

Biomed Support Services Training Curriculum Includes:

•

Principles of Electrosurgery

• LigaSure™ Vessel Sealing Generator

• Force FX™ –C Electrosurgical Generator C

• Force EZ™ Electrosurgical Generator

• ForceTriad™ Energy Platform

• Valleylab™ FT10 FT Series Energy Platform

• Getting the Most From Your BC Group ESU-2400

Learn more about Biomed Support Services at www.biomedsupportservices.com.

You can also reach Biomed Support Services at 303-525-3393, or by

email at dale@biomedsupportservices.com.

Meet Madeline Roche, the New Quality

Manager at BC Group

With four months into her new position as BC Group’s new Quality

Manager, Madeline Roche is already bringing fresh perspectives to BC

Group’s quality system while learning the basis on which they were

formed. Madeline graduated from Northwestern University with a

degree in Biomedical Engineering. She’s been in Quality roles for 14

years, with her first job working as a Validation Engineer for a

small company that made dialysis machines in the Chicagoland area.

She switched to the pharmaceutical manufacturing industry for 11

years at facilities producing radiological imaging agents and

biopharmaceuticals. Both sites were part of large companies with

multiple operations around the world. Madeline held roles in

Validation, Quality Assurance and Quality Control. During this time,

she also earned an MBA from Webster University and became a

six-sigma green belt.

As

the new Quality Manager, Madeline oversees BC Group’s quality system

which maintains the company’s ISO and FDA standards. Madeline's

immediate plans for the organization include improvements to the

internal auditing program and a new, more robust training program to

facilitate continued growth. Madeline has already started working

with multiple departments on improving their documentation and she

hopes to continue to foster an environment of quality focus and a

continual improvement mindset.

We

asked Madeline about the importance of quality for a company, “We

have all experienced a time when we were frustrated by a product

that did not work correctly or did not meet our expectations.

Quality is important because making a high-quality product leads to

satisfied customers.” Madeline also pointed out that an excellent

quality program is especially important for OEMs because in the

medical industry, quality is even more important as products help

ensure the correct operation of hospital equipment, potentially

improving a patient’s treatment.

When a biomed is purchasing test equipment, Madeline recommends

ensuring that a firm is ISO certified and FDA registered when

applicable, as certain systems must be in place and an accreditation

body will confirm them in an audit. Madeline stated, “This takes the

burden off the customer as they can trust in the review already

performed by the independent party.”

When

not at work, Madeline enjoys spending time with her family. She has

two young children who keep her and her husband busy and

entertained. As a family, they enjoy traveling together and seeing

new places. In 2016, they took an Alaskan cruise and toured the

White House. Madeline and her family will spend this holiday season

in New Zealand and Australia.

RTI Cobia Series

Now Available From BC Group

RTI

Electronics’ Cobia series of advanced x-ray quality control

equipment is now available from BC Group. There are four versions of

the Cobia, including the Cobia Smart, Cobia Flex, Cobia Sense and

Cobia Dental.

COBIA SMART

Cobia Smart is

a simple-to-use instrument for checking that the output from an

X-ray tube is correct. Place it beneath the X-ray tube, take an

X-ray exposure and instantly get an accurate reading. The measured

values can be read directly from Cobia Smart’s large and clear

display, even from a distance.

Cobia

Smart has a very clear and rotatable color display, so you can read

off measurement results fast and easily – even from a distance. The

innovative and smart display even shows the results right way up in

measurement situations where the instrument needs to be positioned

upside down.

COBIA

FLEX

The Cobia

Flex offers

you the convenience to make your X-ray Quality Control as quick and

accurate as possible. The Cobia Flex has an internal detector,

offers ability to connect different probes and ion chambers and has

built-in mAs. The measured values can be read directly from the

large and clear display and stored in the Cobia Flex to read later.

Cobia

Flex users also has the possibility to use a tablet or a PC, saving

data to computer, printing reports, using analyses and much more.

The X-ray QA software, Ocean, exhibits the Cobia’s capabilities and

adds benefits that make the work flow more practical and simple.

Ocean makes it possible to perform remote X-ray QA measurements with

your Cobia Flex. You simply connect to your Cobia Flex via Bluetooth

or with a USB cable to your PC or Tablet – then measure.

With

the addition of Ocean Professional, the Cobia Flex truly becomes an

indispensable X-ray QA tool. Perform your QA work without any

worries – sensitivity, kV-ranges or waveform types. It is automatic!

COBIA SENSE

Cobia Sense is

dedicated for use with an external detector such as RTI Dose Probe,

Light Probe, CT ion chamber or external mAs probes. The wide

selection of external probes enables a big flexibility in the

performance of regular constancy checks for most modalities. The

measured values can be read directly from the large and clear

display, and are stored in the Cobia Sense for later viewing.

As the

newest member of the Cobia family, Cobia Sense has the same form

factor and large display which features the Cobia’s familiar and

easy-to-navigate menu structure. The Cobia Sense is targeted for

routine constancy checks, with the ambition to make those tasks

quick and easy.

Thanks

to the Plug-and-Play functionality the Cobia Sense will

automatically recognize the different detectors you connect and

instantly be ready for your measurements. This together with the

easy-to-read display, Cobia Sense is the perfect tool also for

untrained users.

With

Cobia Sense there is no need to reset between your measurements, so

you can remain in the control room until all your measurements are

made. The practical data log allows you to store measurements for

later viewing.

COBIA DENTAL

Cobia Dental is

a simple-to-use instrument for checking that the output from Dental

Intraoral X-ray tube is correct. Since the Cobia is so easy

to

position and doesn’t require any complicated settings, anyone who

works in the dental clinic can quickly and easily perform the

routine inspection of the intraoral X-ray equipment.

The Cobia Dental is especially suitable for

acceptance test, constancy test, and routine quality control of

Intraoral X-rays. The basic need for a dental clinics calibration

check of kV and exposure time is covered with the standard kV model

of Cobia Dental. With a small addition to price, dose, total

filtration and HVL measuring will also be included.

Order the NEW Oxygen Monitor

The

new OXG-1900-A and OXG-1900-M are oxygen monitors with auto

diagnostics. The OGX-1900 Series offers a large, backlit display

with an integral tripod stand and dove tail bracket. A proprietary

advanced galvanic sensor is capable oxygen analysis from 0-100%,

with 60 months of expected life in air. The OGX-1900 Series operates

1,500 hours on 2 AA alkaline batteries.

The

OGX-19000-M upgrades with a low limit alarm.

View the

OGX-1900-A or

OGX-1900-M.

New Release for Ocean, Piranha and Cobia

A new release is

now available for R16-2.2, a software release for Ocean 2014, Black

Piranha and Cobia. This release has been mainly dedicated to

maintenance, but some new features have been added. Listed below are

the main improvements.

OCEAN

• Average Glandular Dose – Support for

the 2016 implemented ACR Digital Mammography protocols. A new AGD

Analysis have been implemented that follows the 2016 release of ACR

Digital Mammography Manual.

• Extended AGD (EUREF) factors up to HVL

of 0.8 mm Al. The AGD applications have got extended conversion

factors to support HVL values in the range 0.6 to 0.8 mm Al.

• Improved Frame Rate calculation

• Dose Per Frame in Mammography Quick

Check. A new application for dose per pulse is implemented for

Mammography Quick Check. It is found under Applications from

Mammography Quick Check.

• Extended energy correction data for

External Dose Probe in mammography

COBIA

• Display Hanging when disconnecting

from Ocean. The Cobia display could hang when disconnecting from

Ocean 2014. This has been identified and resolved with this release.

• Using detector cable longer than 5 m

caused under estimation of dose. Underestimation of dose have been

reported using detectors with long cables. The error was identified

and resolved with this release.

Learn More

Mike Clotfelter and Kristi Boyce (2nd and

1st from the right) from BC Group International joined other members

of the Georgia Biomedical Instrumentation Society as they witnessed

Governor Nathan Deal sign the Proclamation Healthcare Technology

Management Professional Appreciation Week at the State Capitol on

5-23-2017.

BC Group and RTI Forge Distribution Relationship

BC Group

International, Inc. and RTI Electronics, Inc. Towaco, NJ have

announced a partnership between the two organizations for the

distribution of the RTI Imaging product line. BC Group is a leader

in manufacturing, servicing and selling biomedical testing equipment

and RTI is a leader in manufacturing, servicing and selling imaging

testing equipment.

“BC Group

is excited to add the RTI product line to our BC Market Place

offering. BC Marketplace provides over 75 product lines of test

equipment and tools in addition to our extensive offering of BC

Biomedical products,” said Mel Roche, President of BC Group. “We

have been looking to expand our Marketplace offering to include

Imaging Test Equipment for some time now. With RTI’s great

reputation and outstanding product offering, it is the perfect

product line to fill out our ONE STOP BIOMED SHOP concept,” said

Roche.

“This is a

perfect match and we look forward to expanding our coverage with

this new partnership with BC Group,” said Fran Hackett, CEO of RTI.

“BC Group will be marketing all of the RTI products, including the

Black Piranha and all its options,” said Hackett. “The Black Piranha

with its industry leading two year calibration cycle and up to

10-year warranty makes X-ray QA easy, fast and foremost, the most

cost effective solution,” added Hackett.

You can view all the RTI and BC Biomedical products on the BC

Group’s extensive online store at: www.bcgroupstore.com or

you can contact a sales representative at 1-800-242-8428 or

1-314-638-3800 for a quote.

Preorder the New IPA-3400 Infusion Pump Analyzer

Click here to see this product’s page on our webstore.

The IPA-3400 is the

newest addition to the line of BC Biomedical test equipment. With

its large 7” touch screen display, dual syringe stepper motor driven

system and built-in autosequences, the IPA-3400 is the most compact

and fully featured four channel analyzer on the market. The IPA-3400

has full touch screen control of all processes, leaving no need for

buttons and knobs.

The IPA-3400 Infusion

Pump Analyzer also features a new cutting edge, Patent-Pending

design that uses a dual syringe stepper motor driven system. This

provides continuous monitoring of the fluid flow whereas older

technology needs to stop and perform intermittent drains. The

IPA-3400 provides a more realistic flow path for the infusion device

being tested, as well as more accurate readings. The independent

stepper motor control of the custom designed, ceramic valving

allows the system to run quietly and smoothly, with a bidirectional

powered fluid flow for use in the built in cleaning cycle.

The IPA-3400 has built-in

autosequence capabilities that allows the user to perform automated

test procedures. Users can run specific test routines specified by

various manufacturers, saving time as well as reducing the risk of

human error. Advanced features in our autosequences even allows the

inclusion of pictures to aid with the setup and configuration of

each step. All test results are stored internally in the large, 32

GB memory. Results can also be downloaded to a USB flash drive or

directly to a PC.

There are specific

requirements in IEC 60601-2-24 for flow readings, back pressure

simulation, bolus (PCA) measurements and occlusion alarm monitoring.

All of these features are specifically built into the IPA-3400 with

simple to use on screen selections.

The IPA-3400 is designed

to hold up to 4 IPA-3900-FM flow modules. These modules are

individually serialized and calibrated so that they may be moved

from channel to channel and even unit to unit. Once installed they

are recognized by the IPA-3400 and their Serial Number and NIST

Traceable Calibration information are presented on the display and

utilized in all data reporting.

The interchangeable

modules provide the user with unprecedented flexibility in their IPA

Testing System. There is no need to be down when the unit is due for

calibration. Only the modules need to be calibrated. This also

allows the rotating of modules or the use of a spare module, thus

providing flexibility not available in other systems. The same is

true for service. If there is a problem on one channel, only the

module needs to be serviced, eliminating downtime.

The IPA-3400 display may

be raised to gain full access to the four user swappable flow

modules. No wiring or plumbing is required for module

installation. Simply lift the display, remove the cover plate,

loosen the retainer screw and slide the module out. All plumbing and

electronics are self-contained and all electrical connections are

made via a slide-in mating connector on the end of the module. Then

just reverse the process for installation.

The IPA-3400 allows for

easy field expansion. You can buy a 1 channel unit and later

purchase additional modules that can be added in the field. Just

plug them in and the system will automatically recognize the

additional module(s), reconfigure itself and you are ready to go.

To preorder or for more

information about the IPA-3400, expected to be available Q4 2016,

contact BC Group at 1(800)242-8428 or by email at

sales@bcgroupintl.com.

BC Group Releases the New CONMED System 2450

and 5000 Automatic Autosequence

Testing with your

ESU-2400 Analyzer has gotten even easier! Automatic autosequences

are now available for the CONMED System 2450 and System 5000

Generators using the ESU-2400 Series and CONMED

Automation Kit.

The CONMED Automation Kit

(part number BC20-00133) contains the CONMED Footswitch Cable and

CONMED Communications Cable for use with ESU-2400 Series. Using this

kit allows users to perform automated testing using the ESU-2400

Series Autosequence function. The CONMED Automation Kit allows the

ESU-2400 to remotely configure CONMED System 2450 and System 5000

Electrosurgical Generators and trigger the generator output without

user intervention.

The CONMED Automation Kit

is required for the ESU-2400 Series fully automated CONMED PM

Autosequence. There is also a manually triggered autosequence for

the ConMed System 2450 and 5000 using the ESU-2400 Series and

Monopolar Handpiece Simulator.

The CONMED Automation Kit requires an ESU-2400 running Software

v1.0.4.0 or later or an ESU-2400H running Software v1.1.6.0 or

later.

Download software updates HERE.

Also available to download is the new autosequence for the Valleylab

FT10™ Generator. The autosequence is user triggered and requires

the Footswitch

Port Adapter (BC20-03050).

Download your free autosequences HERE.

The ESU-2400 Electrosurgical Unit Analyzers also has

a new software update, which renews compatibility with the new

Covidien ForceTriad™ Software Update 3.8. The new ForceTriad™

Software 3.8 adds compatibility with more accessories. The

ForceTriad™ can now automatically detect a wider range of

accessories that are plugged into the generator.

When using the ESU-2400, the analyzer reads the software version of

the ForceTriad™ and automatically loads the correct autosequence.

All users are required to do is press “Start Triad PM” and the

analyzer determines the correct software version. Additionally,

users can select which autosequence to run. For example, if a user

selects the ForceTriad™ 3.5 autosequence but the ForceTriad™ is

actually 3.6, the ESU-2400 can detect that and tell the user that

they have the wrong autosequence. This includes the new software 3.8

as well.

Download software

updates HERE.

An update for the ESU-2400H will be available soon.

For more information about free autosequences, software updates or

BC Biomedical Test Equipment, visit our webstore at www.BCGroupStore.com.

Mike Clotfelter and Kristi Boyce (3rd row, 2nd and 3rd from the

left) from BC Group International joined other Georgia Biomedical

Instrumentation Society members to have a picture made with the

Georgia Governor at the Georgia State Capital. Governor Deal signed

a proclamation for Biomed Healthcare Technology week for May 22-28

2016.

Philips Ultrasound Validates BC Group’s Ultrasound Leakage Tester

and Probe Adapter

After

many months of conducting an exhaustive evaluation of the BC Group’s

Ultrasound Leakage Tester and Probe Adapter, Philips Ultrasound has

issued the following statement:

“The BC Biomedical

ULT-2020 Current Leakage Tester with the ULT-PA-19 Adapter have been

validated by Philips Ultrasound for use with the X7-2t, S7-3t, and

S8-3t compact connector TEE transducers.”

The testing included the proper fit of the

Compact connector TEE transducers into the ULT-PA-19 adapter, the

testing function and limits used in the ULT-2020 Leakage Tester.

Section 2.2.3B of the IAC Adult Echocardiography Standards for TEE

Testing that went into effect on December 31, 2015 states:

“The manufacturer’s guidelines must be followed for the appropriate

care and cleansing of the TEE transducer and adhere to the

appropriate infectious disease standards to prevent the transmission

of disease. Effective December 31, 2015, the structural and

electrical integrity of the transducer must be checked between each

use, using an ultrasound transducer leakage tester. “Passed” or

“Failed” must be documented in the routine TEE probe cleaning /

maintenance log along with action taken if “failed.”

BC Group’s ULT product line offers everything

you need to comply with the new IAC Standard, including tester,

adapters, conductivity probes, soak trays and a printer to document

the routine testing.

If you would like more information about the

ULT-2020 and ULT-PA-19, please contact us at 1 (800) 242-8428 or by

email at

sales@bcgroupintl.com. If

you would like more information about our line of BC Biomedical

products, visit our website at

www.BCGroupStore.com.

Rice Lake Weighing Systems Awards BC Group for

Outstanding Sales

BC Group is

proud to announce that we have received Rice Lake Weighing Systems’

Award for Outstanding Sales Performance in 2015. BC Group and Rice

Lake Weighing Systems have been partners for years, with BC Group as

a distributor of Rice Lake’s weights and weight sets.

Rice Lake Weighing Systems is a manufacturer of

multiple products, including grip handle and weight sets. Cast iron

grip-handle weights are primarily used to test patient scales by

service technicians. They come in Class F, 7 and M1 weights

BC Group offers

26 different weights and weight sets from Rice Lake. We also have

access to the entire Rice Lake line so if you do not see it on our

webstore, you can call or email us. Each of these have an optional

NIST Traceable Calibration and etched serial number.

If you would

like more information about the Rice Lake weights, please contact us

at 1 (800) 242-8428 or by email at

sales@bcgroupintl.com.

If you would like more information about our line of BC Biomedical

products, visit our website at

www.BCGroupStore.com

The DA-2006-VL Variable Load Bank Has Received FDA

510(k) Clearance

The

DA-2006-VL Variable Load Box

is the newest accessory for the BC Biomedical line of defibrillator

analyzers and has just received FDA 510(k) Clearance. It works in

conjunction with the DA-2006 and DA-2006P Defibrillator Analyzer as

an external load bank. If you already own a DA-2006 or DA-2006P you

can update your software for free to be compatible with the

DA-2006-VL. The DA-2006-VL is used when testing defibrillators to

ensure the proper electrical current is delivered to the heart, per

AAMI DF80 and IEC 60601-2-4 standards. Both AAMI and IEC require

defibrillator analyzers to test a variety of impedances, to simulate

a wide range of patients. With the DA-2006-VL, the DA-2006/P has

test loads from 25-200 ohms and can be measured in 25 ohm

increments.

With the

DA-2006-VL’s advanced technology, it is automatically recognized by

the DA-2006 Series, leaving no settings to change or configure. No

other defibrillator analyzer load bank offers this feature.

The DA-2006-VL

is only compatible with the BC Biomedical line of defibrillator

analyzers. The DA-2006P combined with the DA-2006-VL offers a high

quality analyzer at an unbeatable cost.

If you would

like more information about the DA-2006-VL, please contact us at 1

(800) 242-8428 or by email at

sales@bcgroupintl.com.

If you would like more information about our line of BC Biomedical

products, visit our website at

www.BCGroupStore.com.

CONMED PM Kit Provides the Tools for Automated

Testing of CONMED System 2450 and 5000

The newest addition

to the line of BC Biomedical products is the CONMED PM Kit, a

complete set of accessories needed to safely perform preventative

maintenance procedures. The CONMED PM Kit works with the ESU-2400

Series of electrosurgical unit analyzers to test the CONMED System

2450 and System 5000 electrosurgical unit generators. There are

three pieces to the kit, including a port adapter, 3” jumper cable

and the Monopolar Handpiece Simulator.

The port adapter

that is included allows test leads with standard safety jacks to

connect to the CONMED Systems 2450 and 5000 model generator’s

combination monopolar output.

The Monopolar

Handpiece Simulator is a new accessory for the ESU-2400 Series that

allows technicians to safely and automatically perform leakage

measurements. This works by triggering and measuring handpiece

activated leakage measurements, without manually shorting the

monopolar output terminals. One of the major benefits of automated

testing with the Monopolar Handpiece Simulator is that the

ESU-2400’s autosequences record measurements and produce a report

once the sequence is complete. A technician doesn’t need to manually

record each measurement and doesn’t have to worry about accidentally

skipping a step.

BC Group designed the CONMED PM Kit

specifically for use with the ESU-2400 Series. It is required if a

user wants to properly perform PM autosequences on the CONMED System

2450 and 5000 using an ESU-2400 or ESU-2400H. The ESU-2400 Series PM

autosequences are important for biomedical technicians because it

provides faster and automated testing.

Learn more about the CONMED PM Kit at

www.BCGroupStore.com.

Create Autosequences From a PC or Laptop Using BC Group’s New Safety

Analyzer

BC Group

International has released its newest model of safety analyzer, the

SA-2500. The SA-2500 was created to fill the need for a more capable

and user friendly safety analyzer with AC + DC measurement. The new

analyzer is a portable, durable instrument and has advanced testing

abilities.

The SA-2500

includes all the usual features of a standard safety analyzer,

including line voltage measurement, earth/ground lead

resistance/leakage current, point-to-point testing,

enclosure/chassis leakage current, external resistance and external

leakage current. The SA-2500 has a universal power supply compatible

with line voltages from 90-240 VAC with load currents up to 16

amps. All measurements are true RMS readings. The SA-2500 includes

a variety of other features that separate it from traditional safety

analyzers, including...

Separate

Measurements for AC + DC

With

microprocessor-based technology, the SA-2500 is able to separate and

measure the AC and DC signals. But why would you need to measure AC

and DC? Analyzers that can measure AC and DC separately have an

advantage because some test limits are different for AC or DC

currents. Without separating the measurements and getting specific

results, the worst case scenario must be assumed.

Measures Quality of

Insulation

The

SA-2500 also has the ability to measure the quality of insulation of

a product’s power wiring. This feature ensures that the insulation

of internal wiring is intact and ensures a safe resistance between

the power wiring and any exposed metal parts.

Remote Operation

with Printable Reports

The SA-2500 can

be controlled remotely from a PC or laptop, which allows users to

control measurements and test sequences. Through the Remote

Operation, users are also able to produce reports and print

results from a computer. The Remote Control Software allows the

user to generate automated test sequences, providing for repeatable

and consistent test procedures that can be shared or sent to

technicians as needed.

The SA-2500 is

the newest model of safety analyzer with progressive technology at a

competitive price. For more information about the SA-2500 or for

purchasing information visit the online store at

www.BCGroupStore.com

or speak to a sales representative at (314) 638-3800.

Meet

the Newest Device Designed to Safely Activate Cut and Coag

The Monopolar Handpiece Simulator (part number

BC20-03005) is the newest accessory released for the ESU-2400 and

ESU-2400H Electrosurgical Analyzers. This simulator is the safest

way to test electrosurgical generators by replacing the

electrosurgical handpiece (pencil). The Monopolar Handpiece

Simulator is built to work just like the pencil, but uses internal

relays to activate cut and coagulation (coag). Since it is

controlled by the ESU-2400 or ESU-2400H, this simulator also allows

further automated testing of more electrosurgical generators than

ever before.

Using the same connector and wiring as a standard two-button

electrosurgical pencil, the Monopolar Handpiece Simulator can safely

activate the cut and coag output. Until now, biomedical technicians

have had to activate the handpiece cut and coag power by inserting

insulated jumpers into the monopolar output ports. This dangerous

method can severely burn biomedical technicians. This harmful

situation is easily avoided by using BC Biomedical’s new simulator.

The Monopolar Handpiece Simulator is a

versatile instrument, designed for use with any electrosurgical

generator that utilizes a standard three-pin monopolar port for

electrosurgical pencils. Compatible models include:

|

• Conmed System 5000

• Conmed System 2450

• Coviden ForceTriad™

• Covidien ForceFx

• Bovie Generators |

|

Today Governor Nathan Deal signed a

declaration to mark May 17-23 as Healthcare Technology Management

week in Georgia. Kristi Boyce and Mike Clotfelter joined several

other Georgia Biomedical Instrumentation Society members to

celebrate this event.

About the company

BC Group was founded in 1988. The company was formed as a sales and

service organization to handle the test equipment needs of the

worldwide biomedical engineering community. Over the past 20 years

BC Group has grown to include over 75 Product Lines with thousands

of products.

Originally, BC Group sold only test equipment manufactured by other

companies. Then, in 2000, we began a program of both manufacturing

and private-labeling our own products under the now familiar Green

and Gold "BC Biomedical" label.

In January of 2005, Lloyd Industries, the company that engineered

and manufactured most of the BC Biomedical brand products, purchased

BC Group. This acquisition has provided BC Group with the

engineering and manufacturing resources to expand at an even faster

pace. BC Group, under the "BC Biomedical" brand, is now one of the

largest manufacturers of Biomedical Test and Measurement Equipment

in the world.

Our “One Stop Biomed Shop” theme sums up our business. Our model is

to provide, in one location, all of the equipment, tools and

supplies that the Biomed Community might need. We not only offer an

extensive listing of test equipment manufactured by us and our many

partners, but we also provide labels, cables and everything

in-between.

Meet Mike

Clotfelter: The Man Behind the Company

Mike Clotfelter is the VP of Business Development for BC Group

International. He started with the company in 1999 and has well over

25 years of experience in our industry. Mike’s history as both an

end user and product provider gives him an invaluable point of view

that he has used to help hundreds of members of the biomed

community. This perspective helped to form, develop and improve the

products manufactured and distributed by BC Group, helping to

develop their “one size does not fit all” concept, bringing a

broader selection of products to the field.

During his tenure at BC Group, Mike has focused on the development

of major account and new opportunities. He has cultivated many new

markets and product lines for BC over the years, identifying need

and opportunity and putting in the sweat needed to help a business

grow. His efforts account for a large part of the over 400% increase

in sales BC has experienced in the last 10 years.

For nearly 15 years, Mike worked at Datex-Ohmeda where he managed

the Vaporizer Calibration Lab, Metrology Lab, Mechanical Equipment

Service Center as well as the tools and test equipment for their

Field Service Engineers. His foundation in quality has been

instrumental in BC Group’s own quality efforts, combining simple

solutions with a drive for continual improvement. Mike has been a

key player in the implementation of the ISO 9000, ISO 17025, ANSI

Z540 and ISO 13485 quality systems at BC Group.

Mike possess a wealth of knowledge in both the Med Gas and

Anesthesia fields, resulting in a rare skill set which he uses on a

daily basis to counsel technicians faced with an ever expanding list

of responsibilities and modalities. His focus on finding the right

tool for the job has saved many departments from making some very

expensive mistakes when purchasing new equipment. Over the years,

many have found themselves pleasantly surprised by Mike as he talks

them out of buying unneeded and expensive features or remind them of

that small but critical item that would have cost them a week that

they didn’t have.

Mike has been very devoted to supporting local and state biomed

societies, trade shows and helping biomeds with any problems they

encounter. You can always count on Mike for answers.

GBIS is very proud to award BC Group the 2012 Vendor of the Year

Award.

-Horace

Hunter, Executive Director

Prior Events

BC Group formally introduced the new ESU-2400 full-featured

electrosurgery (ESU) analyzer at the 2009 AAMI Exposition in

Baltimore, MD. The new ESU-2400 will be shipping in the 3rd Quarter

of 2009. The ESU-2400 shatters all previous limitations for high-end

electrosurgery analyzers and provides a level of technology and

capability never before available. For more information, simply call

us or e-mail your questions to esu@bcgroupintl.com. You can also

download several informational documents on our new ESU-2400 in PDF

format at the following links:

ðESU-2400

Product Overview Document

ðMay

2009 Medical dealers Magazine Article on the ESU-2400